Date: March 28, 2025

By: Joe , Lead Engineer at Force, Your Factory-Direct Partner for Industrial Tie Down Solutions

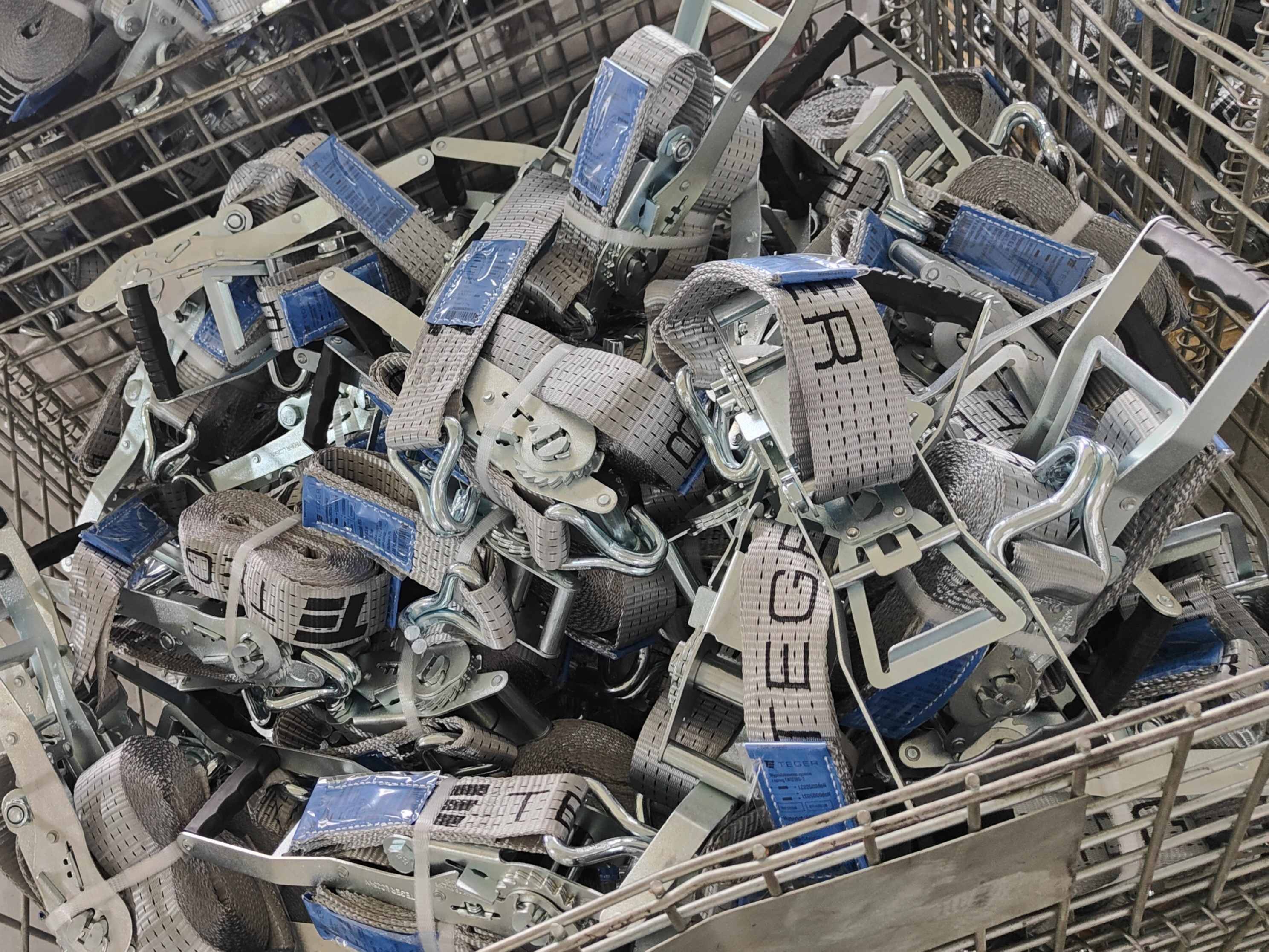

In the high-stakes world of logistics, securing a load isn’t just a task—it’s a mission. Force Rigging, a trusted name in rigging solutions, unveils its ultimate guide to mastering ratchet tie-down straps in just five minutes. Backed by decades of expertise and rigorous testing, this step-by-step breakdown empowers procurement managers and logistics teams to secure cargo like pros—saving time, cutting costs, and ensuring safety. Here’s how it’s done, with real-world examples, technical insights, and tools certified to global standards.

Why Ratchet Straps Are a Game-Changer

A loose load can spell disaster—damaged goods, delayed shipments, or safety hazards. Take the case of a Midwest trucking firm that lost $50,000 in equipment due to a poorly secured flatbed load in 2023 (source: Transport Topics). Ratchet straps, when used right, prevent these headaches. “We often hear from clients asking what the lines on our straps mean,” says Joe, Force Rigging’s Lead Engineer with 10 years of rigging design experience. “Our answer? It’s about strength and trust—here’s our proven approach.”

Force Rigging’s ratchet straps, compliant with EN 12195-2 and CE standards, feature 50mm-wide, 5-ton breaking strength webbing—UV-resistant and built to last. They’re the backbone of efficient cargo control.

Step 1: Threading Like a Pro

Start with the basics:

1. Fully Open the Ratchet – Press the release catch to extend the mandrel (2-inch steel spindle, tensile strength: 800 MPa).

2. Feed the Strap – Slide the 50mm polyester webbing ( abrasion resistance: 7,000 cycles) through the slot.

3. Loop It Over – Pull the strap back over the mandrel for a secure anchor.

4. Adjust Snugly – Leave slight slack; tension comes next.

Real-World Example: A Force Rigging client in Shanghai secured 20 tons of steel pipes for a 500-mile haul using this method—no shifts, no damage.

Step 2: Securing and Tightening

1. Attach S-Hooks – Hook the forged steel ends (proof load: 2.5 tons) to anchor points.

2. Remove Slack – Pull the strap gently.

3. Crank Tight – Pump the ratchet (gear ratio: 4:1) until the load’s firm—our lab tests show it holds up to 5 tons without slipping.

4. Lock It – Close the handle to engage the auto-locking mechanism.

Testing in Action: In our Ningbo lab, we subjected straps to 10,000 tension cycles—results confirmed zero degradation, aligning with ISO 9001 quality benchmarks.

Step 3: Releasing with Ease

1. Unlock – Pull the ergonomic release tab (force required: 10N).

2. Pull Free – Slide the strap out smoothly, thanks to non-jamming components.

3. Store Compact – Fold it up for next time.

Field Test: A logistics team in Guangzhou unloaded a 15-ton shipment in under 10 minutes using this technique—efficiency at its best.

Step 4: Storing for Longevity

1. Coil Neatly – Avoid tangles in the 10-meter strap.

2. Store Smart – Keep it dry and shaded; our webbing resists 2,000 hours of UV exposure (per GS standards).

3. Inspect – Check for wear to ensure reliability.

Pro Tip: Hang straps on a rack or use Force Rigging’s gear bag—clients report 30% longer strap life.

What Makes Force Rigging Stand Out ?

Our straps aren’t just tools—they’re solutions. Tested in real-world conditions (e.g., a 2024 trial securing wind turbine blades across Xinjiang), they deliver:

Efficiency: Quick threading slashes downtime.

Durability: 5-ton capacity withstands harsh weather.

Safety: Certified to EN 12195-2, protecting your team and cargo.

“Force Rigging’s legacy is built on innovation,” says Joe Zhang. “Our clients—like a German auto supplier securing 100 pallets weekly—rely on us for precision.”

Why Choose Force Rigging?

Certified Quality: Member of the WTDA, with ISO 9001 and CE credentials.

Technical Specs: Explore our product sheets at joe@forcerigging.com.

Trusted Globally: Used by logistics firms in over 20 countries.

Ready to secure your next load? Visit for the full guide or contact Joe at joe@forcerigging.com / +86 18067355227.

Frequently Asked Questions (FAQ)

1. What do the lines on ratchet straps mean?

The lines indicate the strap’s breaking strength—ours are marked for 5 tons. “It’s a quick visual cue for safety,” explains Joe Zhang.

2. How tight should I make the strap?

Tighten until the load is firm but not strained—over-tightening risks damage. Our ratchets’ 4:1 gear ratio ensures controlled tension.

3. Can these straps handle extreme weather?

Yes! Our UV-resistant webbing withstands 2,000 hours of sunlight, and lab tests confirm performance from -40°C to 80°C.

4. How often should I replace my ratchet straps?

Inspect before each use. Replace if you see fraying or cuts—our straps typically last 2-3 years with proper care.

5. Are Force Rigging straps compliant with regulations?

Absolutely. They meet EN 12195-2, CE, and GS standards, ensuring legal and safe use worldwide.