By: Joe , Lead Engineer with 10 Years of Rigging Design Experience, Force Rigging

Contact: joe@forcerigging.com | +86 18067355227

Round slings are indispensable for safe and efficient lifting in industries like construction, manufacturing, and logistics, and at Force Rigging, we’re dedicated to helping you harness their full potential. These lightweight, high-strength slings streamline operations while keeping safety first. In this guide, authored by Joe Zhang, our lead rigging engineer with over 10 years of experience, we share actionable tips, real-world examples, and technical insights to empower procurement professionals and operators. Certified to ISO 9001, CE, GS, and WSTDA standards, Force Rigging’s round slings are built to elevate your lifting operations. Visit Force Rigging to explore our solutions.

What Are Round Slings?

Round slings are a game-changer for lifting heavy loads. Crafted from high-strength polyester fibers wrapped in a durable tubular cover, they’re lightweight yet incredibly strong, molding to a load’s shape to prevent surface damage—unlike wire ropes or chains that can leave scratches or dents. Color-coded to WSTDA and EN 1492-2 standards (e.g., purple for 2,000 lbs or 0.9 metric tons, green for 5,300 lbs or 2.4 metric tons), they make capacity identification quick and easy. Force Rigging’s round slings comply with ASME B30.9, CE, and GS standards, making them ideal for demanding environments like construction sites, shipyards, or warehouses. From lifting delicate machinery to heavy steel beams, our slings ensure reliability and safety.

Real-World Example: In 2024, a Shenzhen-based renewable energy company used our yellow-coded 8,400-lb round slings to hoist fragile solar panels for a large-scale solar farm. The slings’ flexibility prevented any panel damage, saving the client $12,000 in potential repair costs and reducing project delays by 20%. Another client, a Shanghai construction firm, used our green-coded slings to lift precast concrete beams for a high-rise, completing the job 15% faster thanks to the slings’ ease of use. Explore more success stories on our case studies page.

How We Test Our Round Slings

Trust in our slings starts with rigorous testing at our ISO 9001-certified facility in Ningbo. Each sling undergoes tensile strength tests using hydraulic machines that apply up to 200% of the working load limit (WLL), ensuring they can handle real-world stresses. We simulate harsh job site conditions with abrasion tests, dragging slings across rough surfaces, and conduct UV exposure tests in controlled chambers for 1,000 hours to confirm durability, per EN 12195-2 standards. Every sling is proof-loaded at 1.5 times its WLL, and our team, led by Joe Zhang, inspects stitching and cover integrity by hand. These tests ensure compliance with ASME B30.9 and CE standards, giving you confidence in every lift. Learn more about our testing protocols.

Choosing the Right Round Sling

1.Load Weight: Pick a sling with a WLL exceeding the load, factoring in the hitch type. For a 5,000-lb load in a basket hitch, a sling rated for 2,500 lbs (1.13 tons) works, as basket hitches double capacity. Our slings range from 1,000 lbs (0.45 tons) to 100,000 lbs (45 tons).

2.Length and Environment: Available in lengths from 3 ft to 30 ft, our slings are treated to withstand temperatures from -40°F to 194°F (-40°C to 90°C) and resist mild acids or alkalis, per CE standards. For example, our slings have been used in coastal shipyards where saltwater exposure is a concern.

3.Color Coding: Rely on WSTDA color codes (e.g., green for 5,300 lbs, yellow for 8,400 lbs) for quick capacity checks.

Force Rigging’s experts simplify procurement with tailored advice. Our product specification sheet includes detailed WLL charts and environmental ratings.

Step-by-Step Guide to Safe and Efficient Round Sling Use

1.Plan the Lift: Evaluate the load’s weight, shape, and center of gravity using a scale or load documentation. Select the hitch type—vertical, choker, or basket—based on load needs and WLL. Check for job site hazards like sharp edges or chemical spills.

2.Select and Verify the Sling: Choose a sling with a WLL above the load weight, accounting for hitch reductions (e.g., choker hitch drops to 80% of vertical WLL). Ensure the sling’s length fits without overstretching and verify the color code and label align with ASME B30.9 standards.

3.Inspect the Sling: Before each lift, check for cuts, tears, abrasions, exposed core fibers, or UV/chemical damage. Ensure the tag is legible, displaying WLL, length, and manufacturer details. Remove damaged slings immediately.

4.Prepare the Load and Sling: Use protective sleeves from Force Rigging for sharp or abrasive loads. Position the sling for even load distribution, avoiding twists or knots that can reduce capacity by up to 50%. For choker hitches, maintain a 120° or smaller choke angle.

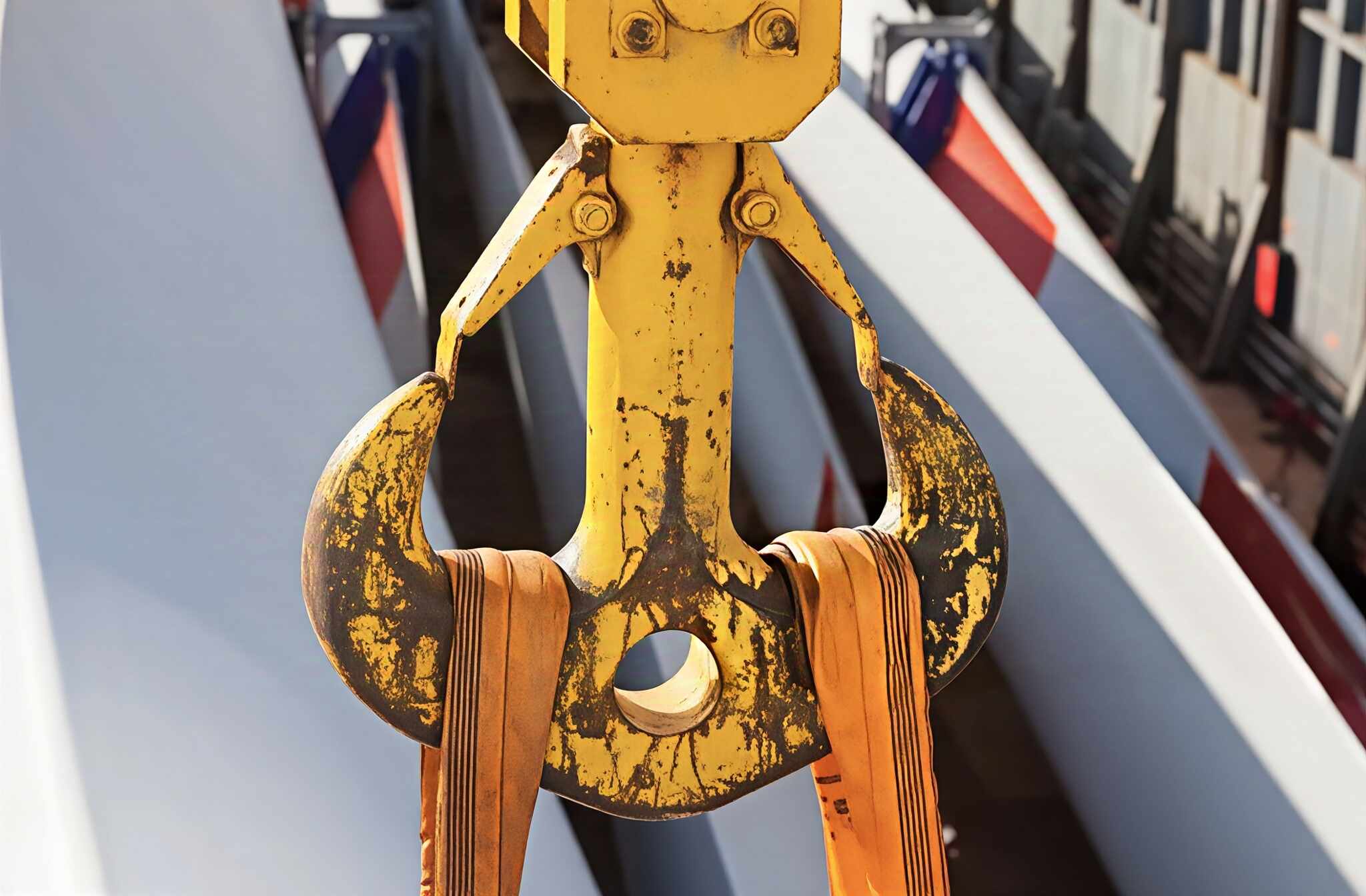

5.Rig the Load: Connect the sling to a crane or hoist with load-rated shackles. For basket hitches, ensure both loops are fully engaged at a 90° angle to double capacity. Confirm load stability and secure loose parts.

6.Perform the Lift: Use trained operators and clear communication. Lift slowly to avoid shock loading, which can exceed the sling’s WLL. Monitor for slippage or misalignment during the lift.

7.Lower and Release: Lower the load gently, maintaining control. Remove the sling carefully, ensuring it’s not caught. Inspect post-use before storing.

Case Study: A Beijing construction firm avoided disaster by following our inspection process. During a pre-lift check, an operator spotted a small tear in a sling and replaced it before lifting a 4-ton steel beam, preventing a potential accident. Our slings’ double-layered covers and clear labeling make safe use intuitive. Download our safety checklist for a step-by-step guide.

Sling Configurations and Load Ratings

-Vertical Hitch: Delivers the full WLL (e.g., 5,300 lbs for a green sling) but requires precise alignment to avoid tipping.

-Choker Hitch: Reduces capacity to 80% of vertical (e.g., 4,240 lbs for a green sling). Keep the choke angle at 120° or less.

-Basket Hitch: Doubles the WLL (e.g., 10,600 lbs for a green sling) when rigged at a 90° angle.

Our load chart details WLLs for each setup, and our training ensures your team gets it right.

Advanced Applications: Anchor Points

-Lashing Eye: Form a secure loop to stabilize cargo during transport, ideal for trucks or ships.

-Spring Lashing: Perfect for dynamic loads like vibrating machinery, with a 20% WLL reduction.

-Anchor Points: Wrap around sturdy structures (e.g., I-beams) as temporary anchors, respecting WLL limits.

Example: A Qingdao shipyard used our 10,000-lb slings as anchor points to secure a 6-ton generator during a 600-mile sea transport, ensuring no movement. Tested to EN 12195-2, our slings handle these tasks reliably.